Wire Rope Sheaves

CATEGORIES

- Wire Rope Info

- 20 - 12 - 2018

- By Wire Rope Australia

Wire sheaves have been around for centuries, being very useful tools for various lifting, pulling and suspension applications. Read on for some basic use, maintenance and safety information on today’s wire rope sheaves.

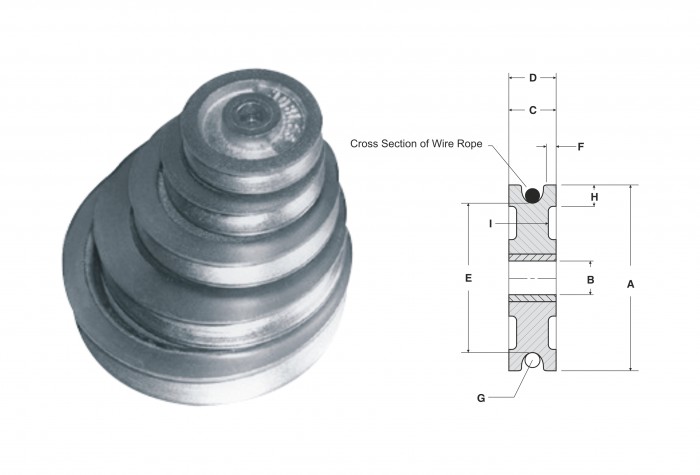

A sheave is basically a wheel with a groove or track on it which guides the wire rope over it. In its simplistic form, wire rope passes over a sheave and connects to the load. The other end of the wire is attached to a pulling device, such as a winch, to gain mechanical advantage. The threaded line over the sheave completes the device. To prevent the wire rope from leaving the groove, the minimum depth of the groove should be the thickness of the rope or cable.

Function

Although the rope sheave has a simple construction, its function is a little bit complicated. You have to determine the exact wire rope diameter to choose the correct sheave size. The groove on a sheave should be flared and slightly larger than the nominal diameter of the rope. If the groove is too big the wire will flatten under load; if the groove is too small, the rope will be pinched. Wire sheaves or pulleys change the direction of the force or increase the pressure to a load. The wire never lays straight in the groove of a sheave because the attached load moves from slide to slide. The movement causes the wire rope to rub against the sides of the sheave, which in turn causes wear.

Maintenance

Like any mechanical system, rope sheaves require maintenance. Here’s some good points to bear in mind:

- Always check the sheaves to avoid delay in your operations.

- Keep sheaves lubricated. Poorly lubricated sheaves create additional friction and accelerate the wear on the shave bearings and centre pins.

- Lack of maintenance increases deterioration of the rope.

Safety Tips

- Pay attention to the sheave groove and the edges of the flange. Any fractures or cracks can cut the rope during operation. General wear on the surface of the sheave could result in a reduction in groove surface, creating an uneven load-bearing surface.

- Regular inspection is necessary. It’s the only way to ensure safe operation.

- Worn out cables and ropes are dangerous to any lifting, suspension and pulling applications. Replace these immediately.

- Remove or replace the sheaves periodically. This prevents large-scale damages. If necessary, replace sheaves with new bearings as well.

- RETURN TO BLOG

-

Stainless Steel Wire Rope

NEXT

1300 166 722

1300 166 722