Selecting Wire Rope for Your Application

CATEGORIES

- Wire Rope Info

- 20 - 11 - 2018

- By Wire Rope Australia

Here’s a few tips to consider when selecting wire rope:

Selecting the appropriate wire rope for your application is important. Inappropriate or incorrect selection wire rope can lead to serious complications. Learn how to avoid this mistake.

Construction and core types determine tensile strength of a specific type of wire rope. Where load-bearing applications are involved, types of wire rope are specifically manufactured in compliance with standards set by regulatory bodies to ensure these products are safe to use.

Safety is compromised mainly when wire rope is in appropriately used or used for applications different from what it was intended to be used. Therefore, critical to maintaining occupational health and safety (OH&S) is making the right wire rope choice.

#1. Understand wire rope construction or core.

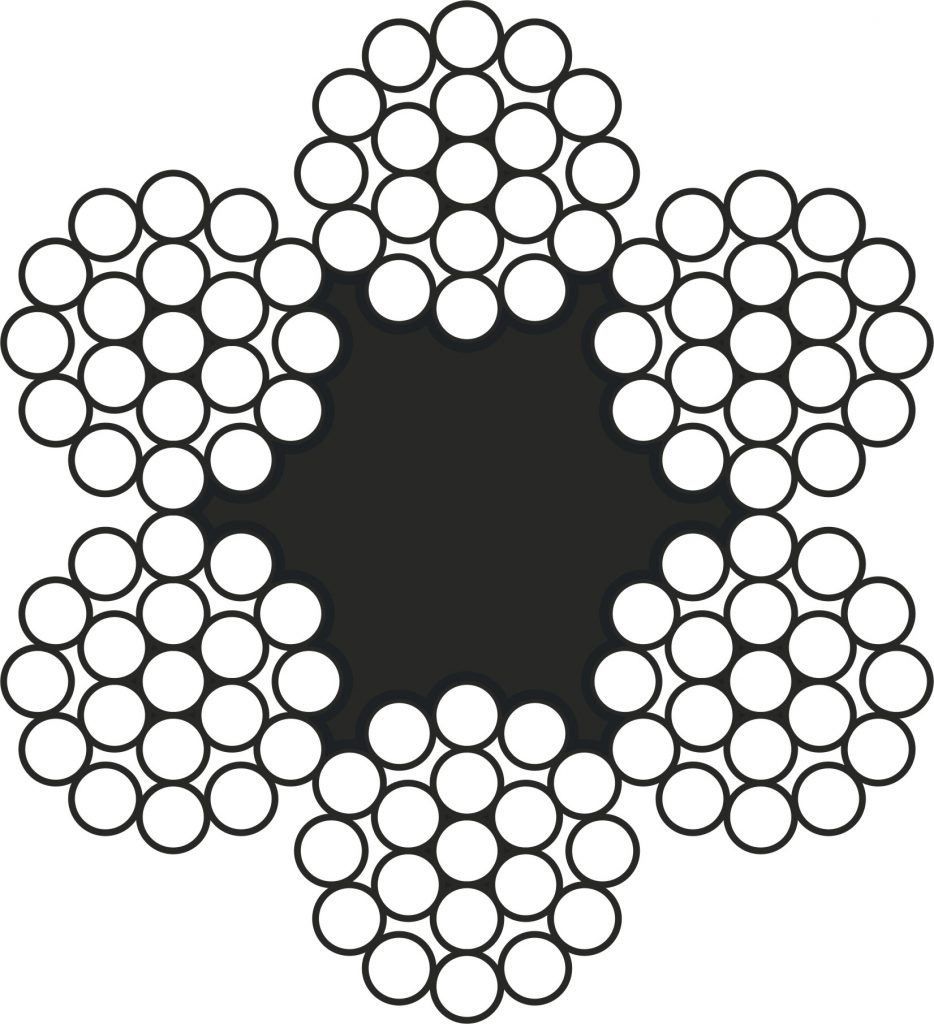

Wire rope is made of individual steel wires spun into a strand. These strands are then closed over a core. Wire rope construction is generally expressed to describe these information. For example, 6×19 FC would refer to wire rope made of six strands, with 19 individual wires per strand, closed around a fibre core. In some cases, the lay-up of wires in a strand plus the direction and type of rope lay are included in expressing wire rope construction. For example, 6×19 (12/6/1) Fibre Core Right Hand ordinary Lay Wire rope core supports strands and maintain their correct positions when working. Fibre core provide increased flexibility; steel cores increased load-bearing strength and resistance to distortion, crushing and heat.

#2. Know your wire rope load limits.

All ropes, even the strongest, industrial-grade wire rope, have a breaking point. In construction, manufacturing, marine, height safety, and other high-risk applications, it is worthwhile to check indicative minimum breaking strains for your options.

#3. Know your rope’s tensile strength.

Wire rope tensile strength determines its breaking strain. Although reviewing wire rope load charts gives you a ballpark, these are indicative figures only. At Wire Rope Australia, we strongly advise checking both grade and minimum breaking strain (MBS) at the time of purchase to ensure manufacturing specifications are factored into the buying decision. Where life and limb is at risk, you can’t be too careful. Be meticulous. Ask your questions. Do your research. Wire rope suppliers who know their business will have expertise on staff to guide you towards making the right choice. Fill out the enquiry form on the right and let us assist you with sourcing you wire rope for your application.

- RETURN TO BLOG

-

Stainless Steel Wire Rope

NEXT

1300 166 722

1300 166 722